When it comes to CNC machining, aluminum is one of the most popular materials used, and for good reason. Its combination of workability, strength, and versatility make it an ideal choice for many different industries, from aerospace and automotive to medical devices and electronics.

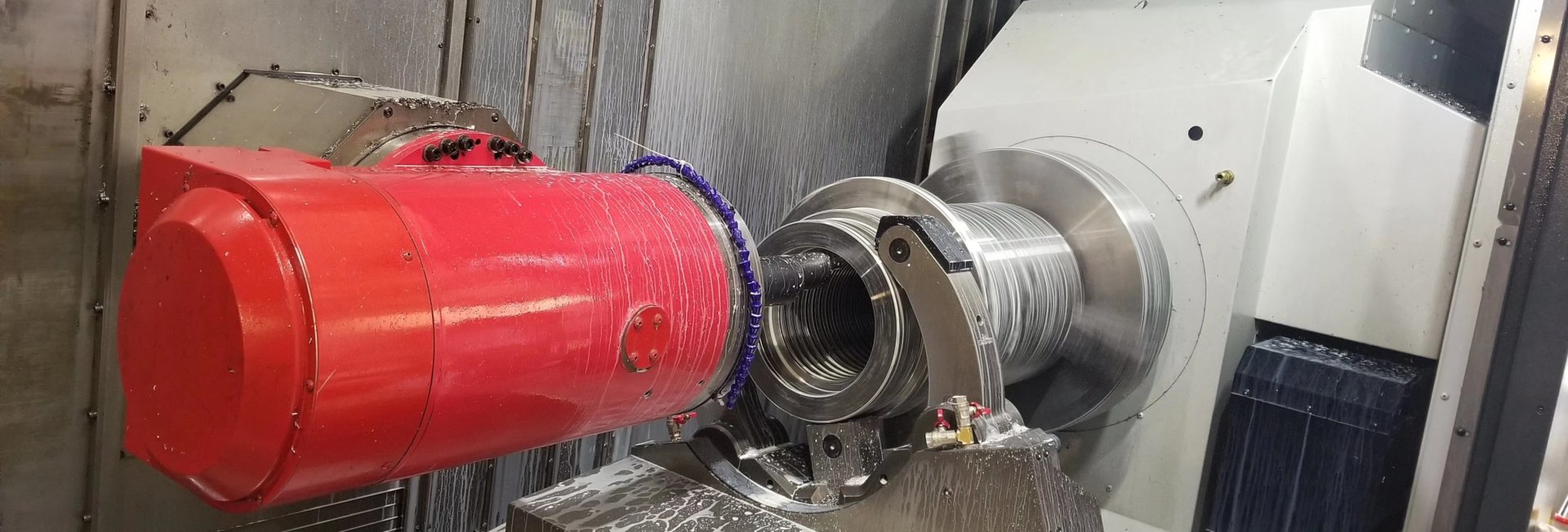

One of the key advantages of aluminum as a machining material is its workability. It is relatively easy to transform aluminum into a variety of shapes and sizes, either through traditional machining or through advanced CNC techniques. These techniques can include milling, turning, drilling, and more, all of which can be used to create complex and precise parts with tight tolerances.

Another advantage of aluminum is its strength. While it may not be as strong as some other metals like steel or titanium, it still has a high strength-to-weight ratio that makes it a popular choice for lightweight structures and components. This is especially important in industries like aerospace or automotive, where weight reduction can lead to improved performance and fuel efficiency.

Yet another advantage of aluminum is its versatility. It can be used to create a wide variety of parts and components, from simple brackets and fasteners to complex assemblies and housings. It is also an excellent choice for prototyping or low-volume production, thanks to its low cost and easy availability.

Of course, as with any machining material, there are also some potential drawbacks to using aluminum. One of the biggest is its tendency to heat up during the machining process, which can lead to deformation or other quality issues. However, with proper tooling and machining techniques, these problems can generally be minimized or eliminated.

When machining aluminum, it's important to use high-quality tooling and equipment that is specifically designed for this material. This can include specialized cutting tools, coolants, and lubricants that are optimized for aluminum's unique characteristics. It's also important to choose a reliable and experienced machining supplier who has the expertise to handle aluminum projects with precision and efficiency.

At (brand name removed), we specialize in CNC machining of aluminum blocks and other materials, using advanced equipment and techniques that deliver high-quality parts and components with minimal lead times. Our team of experts has years of experience working with aluminum and other materials, and we are committed to providing our customers with the best possible service and support.

Whether you need a prototype for a new product, a small run of custom components, or high-volume production of complex parts, (brand name removed) has the expertise and resources to meet your needs. Contact us today to learn more about our aluminum machining services and how we can help bring your ideas to life.