CNC (Computer Numerical Control) machining is revolutionizing the manufacturing industry, enabling the production of complex parts quickly and precisely. Aluminum is a popular material for CNC machining thanks to its low weight, corrosion resistance, and excellent strength-to-weight ratio. Aluminum CNC machining parts find applications in a wide range of industries, such as aerospace, automotive, medical devices, consumer electronics, and more.

In this blog, we'll cover all you need to know about CNC machining aluminum parts: from its benefits and applications to the different machining processes and how to choose a CNC machining aluminum supplier.

Benefits of CNC Machining Aluminum Parts

CNC machining aluminum parts offer several benefits, including:

1. Lightweight: Aluminum has a low density, making it one of the lightest metals.

2. Corrosion resistance: Aluminum forms an oxide layer on its surface, protecting it from corrosion.

3. High strength-to-weight ratio: Aluminum has excellent strength-to-weight ratio, making it a popular choice in industries where lightweight and strength are critical.

4. Machinability: Aluminum is one of the easiest materials to machine, enabling the production of complex parts with high precision and tight tolerances.

Applications of CNC Machining Aluminum Parts

CNC machining aluminum parts are finding applications across a wide range of industries, including:

1. Aerospace: Aluminum is a popular material in aerospace applications such as aircraft frames, engine components, and landing gear owing to its low weight and high strength.

2. Automotive: Aluminum finds extensive use in the automotive industry for cylinder heads, engine blocks, pistons, and suspension components to reduce weight and increase fuel efficiency.

3. Medical devices: Aluminum is a biocompatible material that finds use in medical devices such as implants, surgical instruments, and imaging equipment.

4. Consumer electronics: Aluminum is a popular material for consumer electronics such as laptops, smartphones, and tablets due to its light weight and thermal conductivity properties.

Machining Processes for Aluminum CNC Machining Parts

Aluminum CNC machining parts are produced using several machining processes, including:

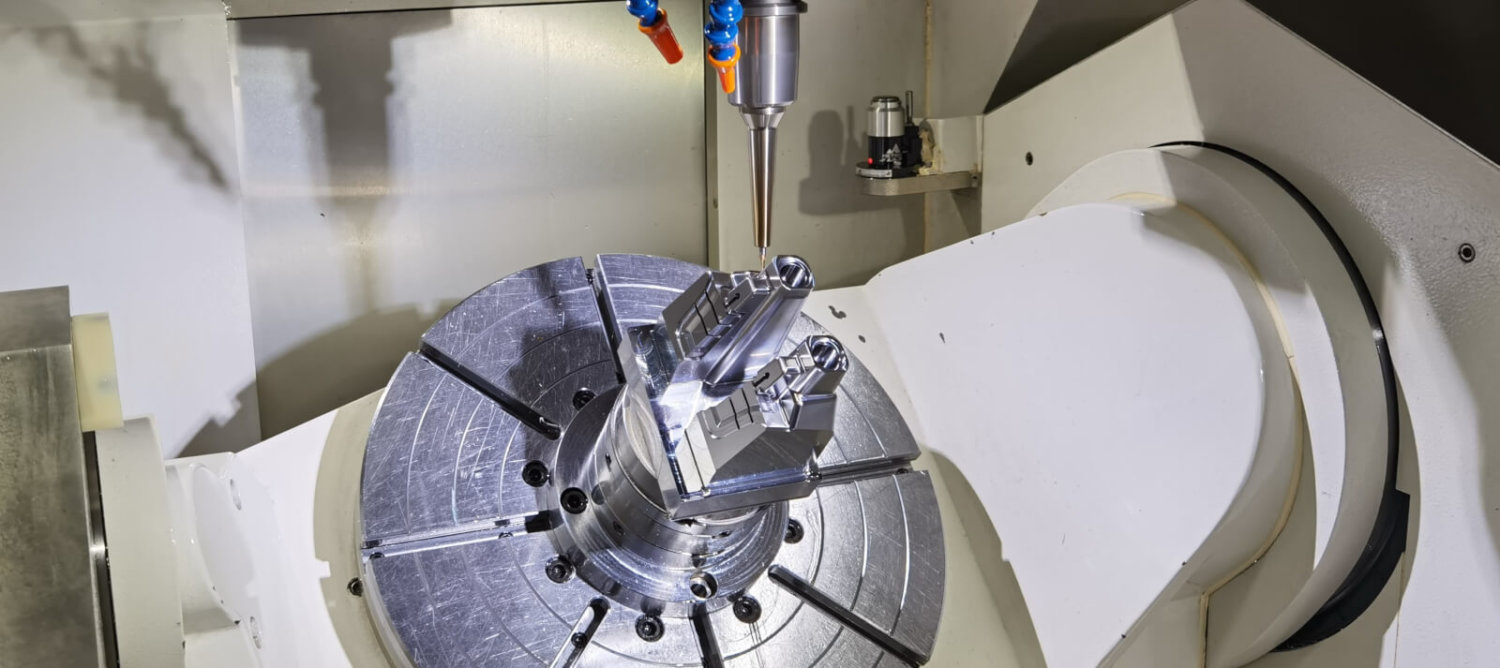

1. CNC milling: CNC milling involves removing material from an aluminum block using a rotating cutting tool to produce the desired shape.

2. CNC turning: CNC turning involves rotating an aluminum rod while a cutting tool removes material to produce cylindrical or conical shapes.

3. Drilling: Drilling involves making holes in an aluminum part using a rotating drill bit.

4. Tapping: Tapping involves cutting threads in an aluminum part using a special tap tool.

5. Boring: Boring involves enlarging a pre-drilled hole in an aluminum part to create a precise and uniform diameter.

Choosing a CNC Machining Aluminum Supplier

When choosing a CNC machining aluminum supplier, consider the following factors:

1. Quality: Choose a supplier that guarantees high quality and precision in their aluminum CNC machining parts.

2. Lead time: Choose a supplier that can deliver your aluminum CNC machining parts within your desired lead time.

3. Cost: Choose a supplier that offers affordable pricing while maintaining high-quality standards.

4. Experience: Choose a supplier that has extensive experience in aluminum CNC machining and a proven track record of delivering quality products.

Conclusion

CNC machining aluminum parts offer several benefits, including lightweight, corrosion resistance, high strength-to-weight ratio, and machinability. They find applications in a wide range of industries, from aerospace to consumer electronics. Aluminum CNC machining parts are produced using several machining processes, including CNC milling, turning, drilling, tapping, and boring. When choosing a CNC machining aluminum supplier, consider factors such as quality, lead time, cost, and experience.