Wire electrical discharge machining (EDM) has been a popular technique used in the manufacturing industry for many years, offering numerous benefits like excellent accuracy, tight tolerances, and fine surface finishes. As technology has advanced, so has the wire EDM process, leading to the creation of sophisticated machines like the AgieCharmilles CUT E series from GF Machining Solutions.

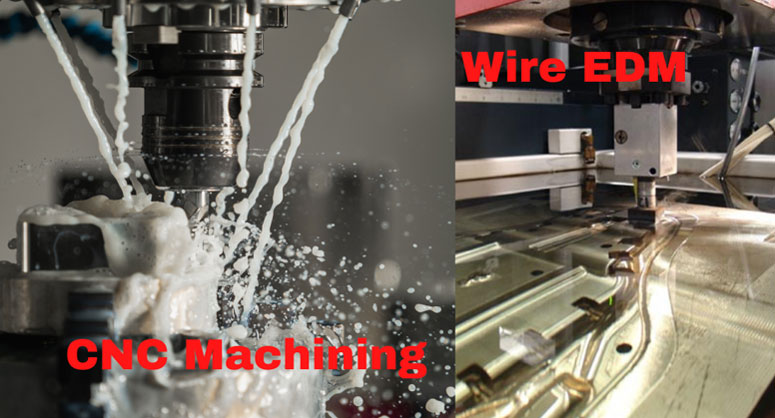

Wire EDM is a non-conventional metal machining process that uses a thin wire to cut through metal parts. This process involves using an electrically charged wire, usually made of brass, to cut through the material with precision. The wire EDM process requires a continuous flow of electrical current through the wire and the workpiece, causing a spark to jump from the wire and create a ‘cutting path’ in the workpiece.

GF Machining Solutions uses Intelligent Power Generator technology in their wire EDM machines to improve the cutting speed, surface finish, and overall performance of the machine. This technology manages the electric discharge process, ensuring that the spark discharge is consistent and stable throughout the machining process.

Furthermore, the digitalization of power generators has enabled the accurate and fast identification of the best parameters and settings for machining a part, driving down manufacturing costs and minimizing cycle time. These wire EDM machines also boast advanced sensors and monitoring systems that help them detect operational abnormalities at an early stage, safeguarding the machines and minimizing disruptions.

Wire EDM machines are used by many industrial sectors, like aerospace, medical, and automotive, for the production of complex and intricate parts. These machines are especially useful when dealing with difficult-to-cut materials like tungsten carbide, titanium, and hardened steel.

In conclusion, wire EDM machines continue to be essential for the production of high-precision parts. Their use in modern manufacturing environments has given us exciting technological advances like Intelligent Power Generators, leading to improvements in cutting speed and surface finish. The continued growth and innovation of wire EDM machines have been instrumental in the success of the manufacturing industry, and with the constant evolution of technology, we expect to see even more improvements to wire EDM capabilities in the future.

If you're in need of wire EDM services for your business, it's essential to research and find reputable wire EDM shops that are equipped with modern machines and experienced technicians. As you search for a reliable wire EDM shop, you must ensure that the services offered align with your company's specific needs, including part complexity, material type, and quantity.

In a nutshell, wire EDM is a beneficial and necessary process that allows for the production of intricate parts with excellent accuracy and precision. As technology continues to advance, we expect to see even more improvements and benefits to this already valuable process.